On board, 25 July 1940. On board, 25 July 1940. |

||

| Report on the supply of U.A., Maschine Section. | ||

| 1) Fuel oil: | ||

| After testing in the home waters, the spiral and rubber hoses were cleaned of the fuel oil residues by thoroughly rinsing them with seawater, hung up to dry and placed in a hatch on the upper deck in the rolled up condition. During the current delivery of oil, it was found that the hose material held up very well with this type of storage and preservation. | ||

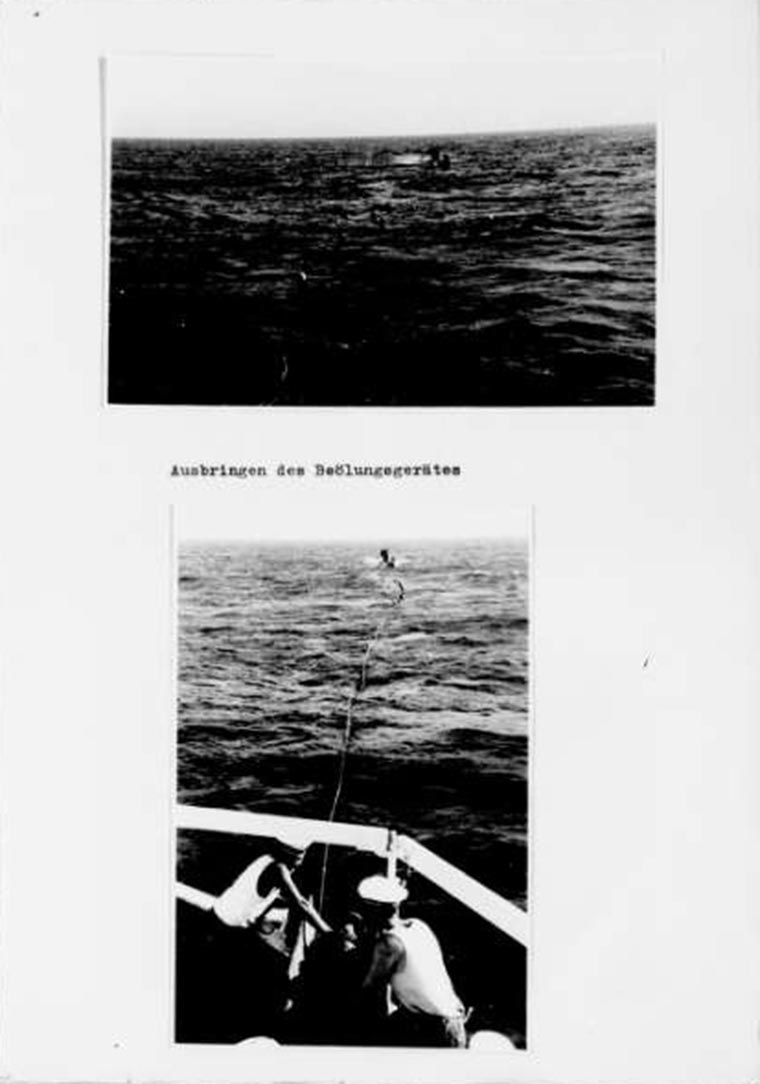

| After establishing the hose connection - as practiced at home - a double, electrically driven piston pump of 140 cbm / hour at H = 30 was used to pump the fuel oil. At a pressure of 2.5 atm at the pump, about 25 cbm were delivered every hour at the beginning of the fueling. This hourly output could have been increased from on board, but an increased output was rejected by the U-boat because the pipe cross-sections were too small. After delivering around 80 cbm, fueling was stopped. Since the submarine did not have a suitable compressed air connector, the oil in the hose could not be pushed back with air on board. The attempt to suck the the oil from the U-boat would have failed because the main length of the hose is about 150 meters consisting of rubber tubing that squeezed together when pumping. It was difficult to retrieve the oil-filled hose. To eliminate this difficulty, a suitable compressed air connection piece was made on board. It should be noted that the U-boat did not have a compressed air hose to connect to the refueling gear, which had to be loaned to the submarine. The second fueling of about 70 cbm had not yet taken place when this report was written. | ||

| In the prevailing strong swell, the spiral hoses attached to the fueling gear often got under the saw of the submarine, whereby 3 spiral hoses were then so badly damaged that they could | ||

|

Click the flag to view the above page from the original German KTB |

- 2 - |

||

| no longer be used. Therefore it is still advisable to use spiral hoses at the beginning of the fueling gear, as these are not as delicate as pure rubber hoses. | ||

| 2) Lubricating oil and cylinder oil: | ||

| The delivery of lubricating and cylinder oil presented no difficulties. The available canisters of 40 liters contents were sent from board to board with a rubber boat. With the prevailing air temperature of about 28 to 35°C the lubricating and cylinder oil was in a thin condition, so that the emptying of the canisters on the U-boat went very quickly. | ||

| 3) Drinking water: | ||

| Drinking water was delivered with the U-boat being towed. Drinking water hose of 65 mm (on board connection) and 45 mm (U-boat connection) was coupled together with a matching adapter and given to the U-boat filled with compressed air. About 16 tons of drinking water were delivered without difficulty. After ending the water delivery the hose was blown out from on board and so floated back on board. | ||

| 4) Equipment: | ||

| Equipment carried for the U-boat was packed in boxes and stored in the holds according to a certain stowage plan. In a very short time, the requests of the submarine could be fulfilled by handing over the requested equipment. | ||

| Enclosure with 5 photos. | ||

| |

||

| Kapitänleutnant and Chief Engineer. | ||

| Seen ! | ||

| |

||

| Kapitän zur See and Kommandant. | ||

|